CASE STUDIES

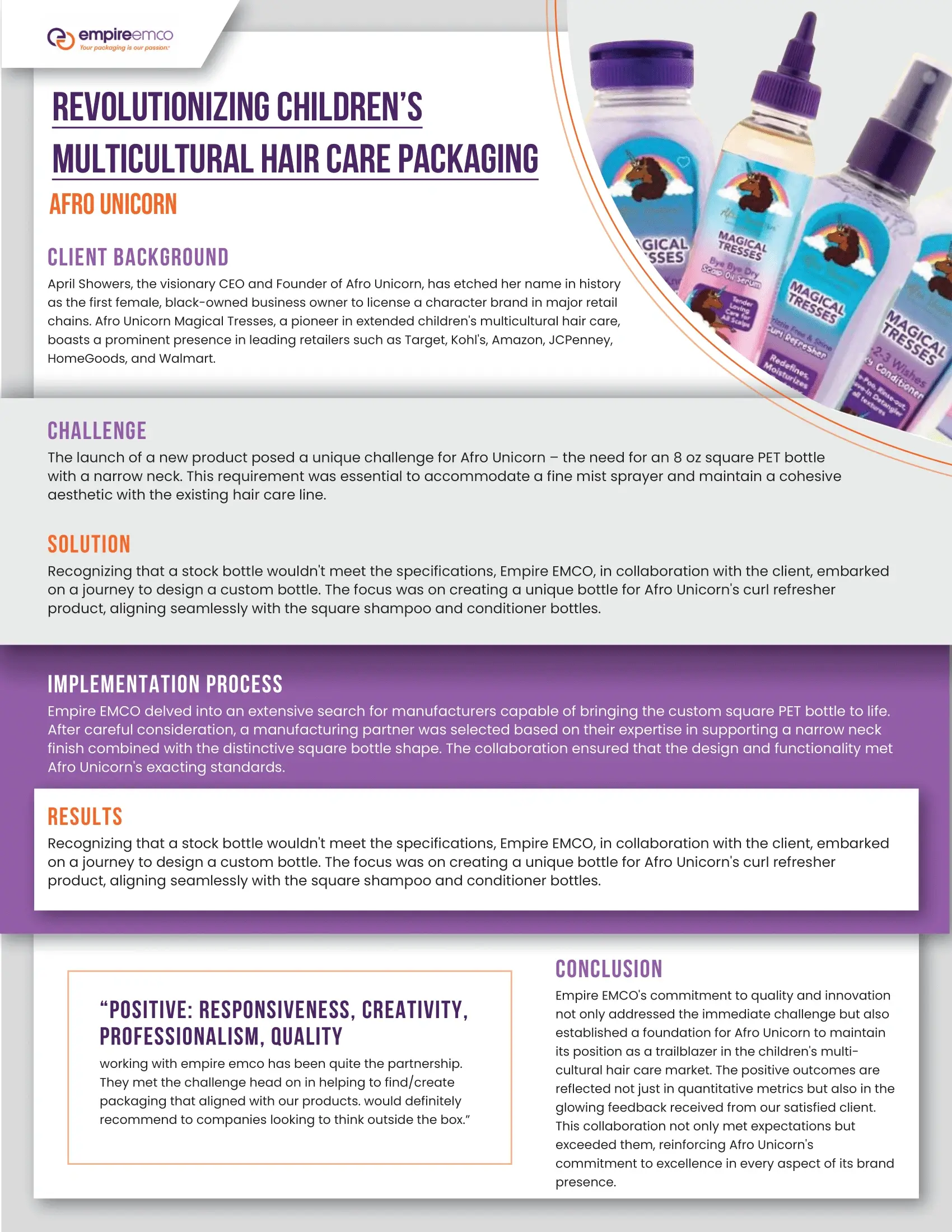

Revolutionzing Children’s Multicultural Hair Care Packaging

CHALLENGE

Afro Unicorn needed a custom 8 oz square PET bottle with a narrow neck to match their existing hair care line and fit a fine mist sprayer—something stock options couldn’t provide.

SOLUTION

Empire Emco worked closely with Afro Unicorn to design a custom bottle that fit the sprayer and maintained the brand’s signature square look across the product line.

Revolutionzing Children’s Multicultural Hair Care Packaging

CHALLENGE

Afro Unicorn needed a custom 8 oz square PET bottle with a narrow neck to match their existing hair care line and fit a fine mist sprayer—something stock options couldn’t provide.

SOLUTION

Empire Emco worked closely with Afro Unicorn to design a custom bottle that fit the sprayer and maintained the brand’s signature square look across the product line.

Problem Solving Resources

CHALLENGE

A specialty foods company struggled with long lead times and poor communication from their packaging supplier, putting production at risk and driving up costs. They needed a reliable partner to source alternative packaging quickly and keep their holiday production on track.

SOLUTION

Empire Emco stepped in with a faster supplier, quicker decision-making, custom packaging, and tighter supply chain coordination to keep production moving without delays.

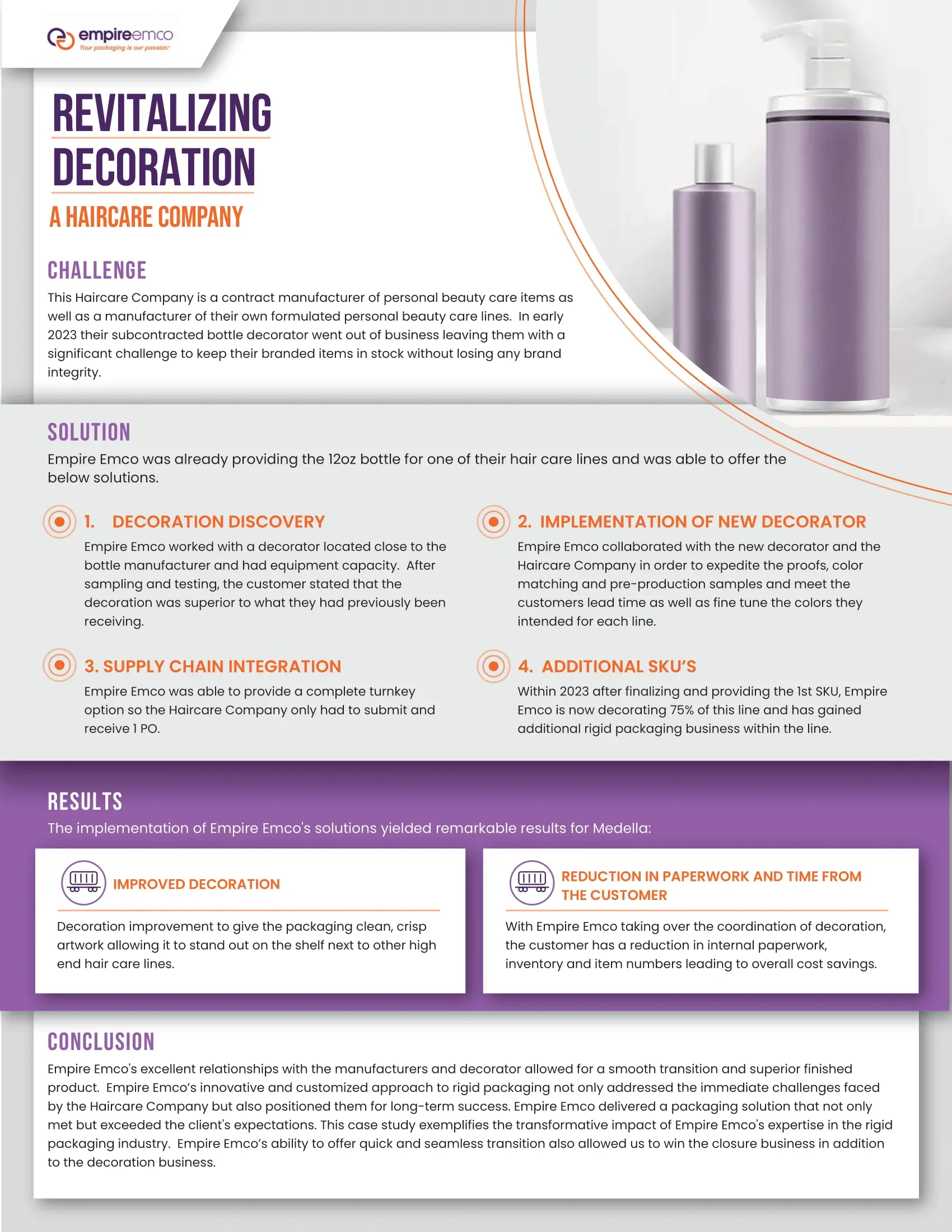

Revitalizing Decoration

CHALLENGE

A haircare company lost its bottle decorator, putting their branded products at risk. As both a contract manufacturer and brand owner, they needed a fast solution to maintain packaging quality and supply.

SOLUTION

Empire Emco, already supplying their 12 oz bottles, secured a new decorator with capacity near the bottle plant. After testing and fine-tuning colors, the new decoration exceeded expectations. Empire Emco streamlined the process with a turnkey supply chain solution, requiring only one PO, and helped expand decoration across 75% of the line.

Revitalizing Decoration

CHALLENGE

A haircare company lost its bottle decorator, putting their branded products at risk. As both a contract manufacturer and brand owner, they needed a fast solution to maintain packaging quality and supply.

SOLUTION

Empire Emco, already supplying their 12 oz bottles, secured a new decorator with capacity near the bottle plant. After testing and fine-tuning colors, the new decoration exceeded expectations. Empire Emco streamlined the process with a turnkey supply chain solution, requiring only one PO, and helped expand decoration across 75% of the line.

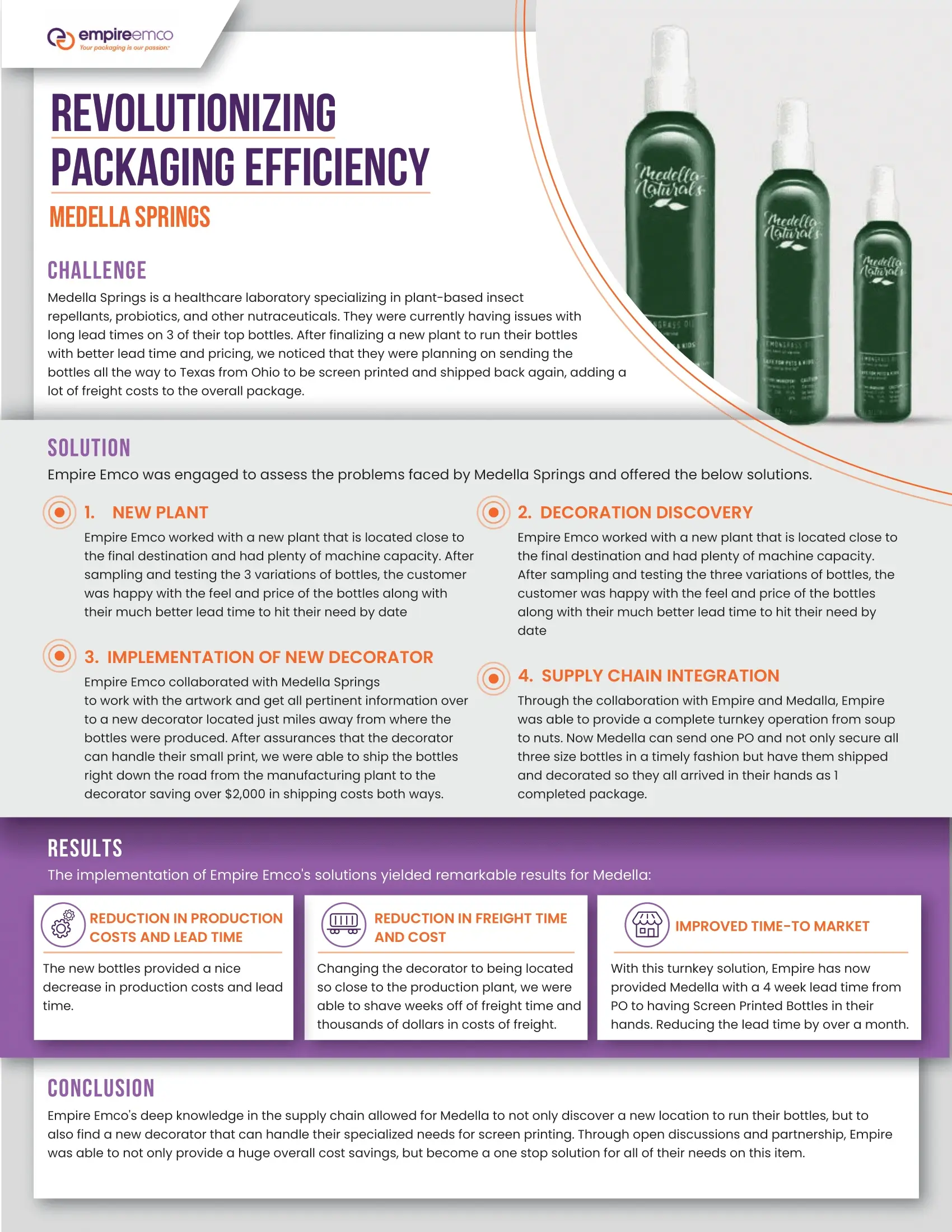

Revolutionizing Packaging Efficiency

CHALLENGE

Medella Springs was facing long lead times on key bottles and planned to ship them from Ohio to Texas for decoration—adding unnecessary freight costs and delays.

SOLUTION

Empire Emco sourced a nearby plant with faster lead times and better pricing, then secured a local decorator capable of handling Medella’s fine print needs. This eliminated the costly shipping loop and ensured on-time delivery.

Plastic Bottle Paneling

CHALLENGE

A personal care brand with plant-based, eco-friendly products was experiencing bottle paneling. Their U.S.-made bottles were paired with caps from China that included a non-vented liner, causing airflow issues with thicker formulas.

SOLUTION

Empire Emco analyzed the issue and identified the need for a vented liner. After testing, the M-Vent liner—featuring an FDA-approved oleophobic membrane—proved to be the best fit for resolving the paneling.

Plastic Bottle Paneling

CHALLENGE

A personal care brand with plant-based, eco-friendly products was experiencing bottle paneling. Their U.S.-made bottles were paired with caps from China that included a non-vented liner, causing airflow issues with thicker formulas.

SOLUTION

Empire Emco analyzed the issue and identified the need for a vented liner. After testing, the M-Vent liner—featuring an FDA-approved oleophobic membrane—proved to be the best fit for resolving the paneling.