Package Customization – A Tailored Solution

In the packaging industry, customization can range from modifying existing stock packaging to developing a fully custom mold. The level of customization depends on branding, functionality, and production requirements.

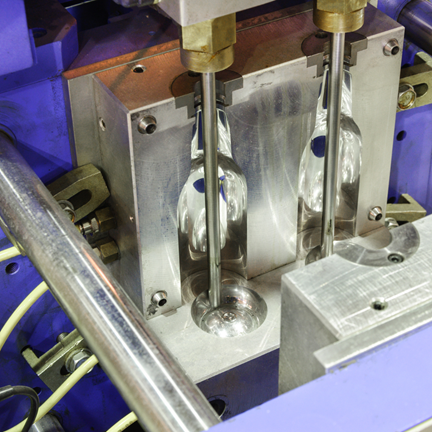

Custom Mold

A custom mold involves the creation of a unique bottle, cap, jar, or closure designed specifically for a product. This process includes:

- New Tooling – Developing proprietary molds for exclusive shapes, logos, or structural features.

- Material Selection – Choosing resins for durability, sustainability, or specialized performance.

- Functionality Enhancements – Custom dispensing systems, tamper-evident features, or child-resistant closures.

A custom mold may also involve:

- Moving an existing mold to a new supplier for sustainability or efficiency.

- Combining a stock bottle with a custom closure, creating a unique solution.

Package Customization

For brands that don’t require a fully custom mold, customization options enhance stock packaging while reducing lead times and costs. These include:

- Color & Decoration – Custom resin colors, silk screening, embossing, or shrink sleeves.

- Specialty Closures – Unique dispensing options such as foamers, aerosols, airless, or dual-chamber systems.

- Material Modifications – Lightweighting, PCR (Post-Consumer Resin), or bioplastic integration for sustainability.

Tailored Solutions for Every Need

Whether creating a one-of-a-kind mold or customizing stock packaging, Empire Emco helps brands differentiate their products with innovative, tailored packaging solutions.

Dreaming of packaging, that’s distinctly yours?

Let's make it happen!

Make your brand unmistakable with our tailored design services. From distinct shapes to eye-catching colors, we bring your vision to life, crafting packaging that not only represents your brand but also grabs attention on the shelf. Let us help you create something truly one-of-a-kind.